Hi, my name is Bob and I am a construction manager. I oversee all aspects of managing the operations of a construction project, including budgets, staffing, and the compliance of the entire construction project.

Hi, my name is Bob and I am a construction manager. I oversee all aspects of managing the operations of a construction project, including budgets, staffing, and the compliance of the entire construction project.

In 10+ years of my experience, I have never had a Business Intelligence (BI) tool. I had to create spreadsheets to track daily activities, calculate risks and build formulas to measure impact. Given the size of the projects I worked on, this was extremely complex. As a result, I would spend a lot of my time putting out fires to solve problems that I knew could have been prevented if I had the right information.

Recently my company introduced BI to our team. Since I’m using BI for the first time, I decided to create an activity log similar to a diary of my project.

Let me share some highlights with you:

October 28, 2011

We are 4 weeks into the project. We have the crew working on the ground. The foundation is done. The structural engineer has finished his design. We are ready to roll.

January 11, 2012

This morning I received an alert about my Preventative vs. Corrective Maintenance. My monthly work mix by type looks like this: preventative 36%; repair 24%; rebuild 5%; and modify 35%. My preventative costs have gone down from an optimal 40% to 36% and my repair costs have increased correspondingly.

When I drilled down into the repairs, I see that we are responding to higher than normal number of heating and insulation work items. I am going to talk to Edward – my HVAC contractor – about it.

February 29, 2012

I have been monitoring our electrical work. Our average Cost per SQ Foot is 13% less than industry average. This is a breakthrough thanks to the changes I have made monitoring the project with BI and making data-driven decisions. It lets me monitor these costs on an ongoing basis, so I can take preventative actions to stay below industry average to protect our funding and even justify additional headcount.

March 16, 2012

Productivity Rate is one of my favorite indicators – because it truly provides me with real-time info about the performance of my team. On average, our productivity rate has been at optimal levels. However, the plumbing trade group’s actual cost is exceeding the estimated costs. This will affect my cost-to-complete and margins, as I have to pay overtime for this contractor.

But I don’t have to worry… my BI tool let me drill into this indicator to see whether the reason is ‘labor’ or ‘supply’ related. Drill-thru was something a spreadsheet never let me do before.

March 30, 2012

Two weeks have passed since I shifted resources for plumbing. Our productivity rates have improved since then and the project is looking on time and on budget.

With 40 more days to go, I want to make sure we deliver on time and meet our SLA with the building owners. I see no bottlenecks. Cycle Times – the average time to complete an activity – shows me that we are actually 4 days ahead of the schedule.

May 21, 2012

I’m very happy to report that we are done with the construction. The ROI on this project was greater than we expected and my client is very happy. Next weekend is the Memorial Day weekend. I have the time and money I need to take a nice vacation with my wife and son.

-As told by Bob, a fictional construction manager.

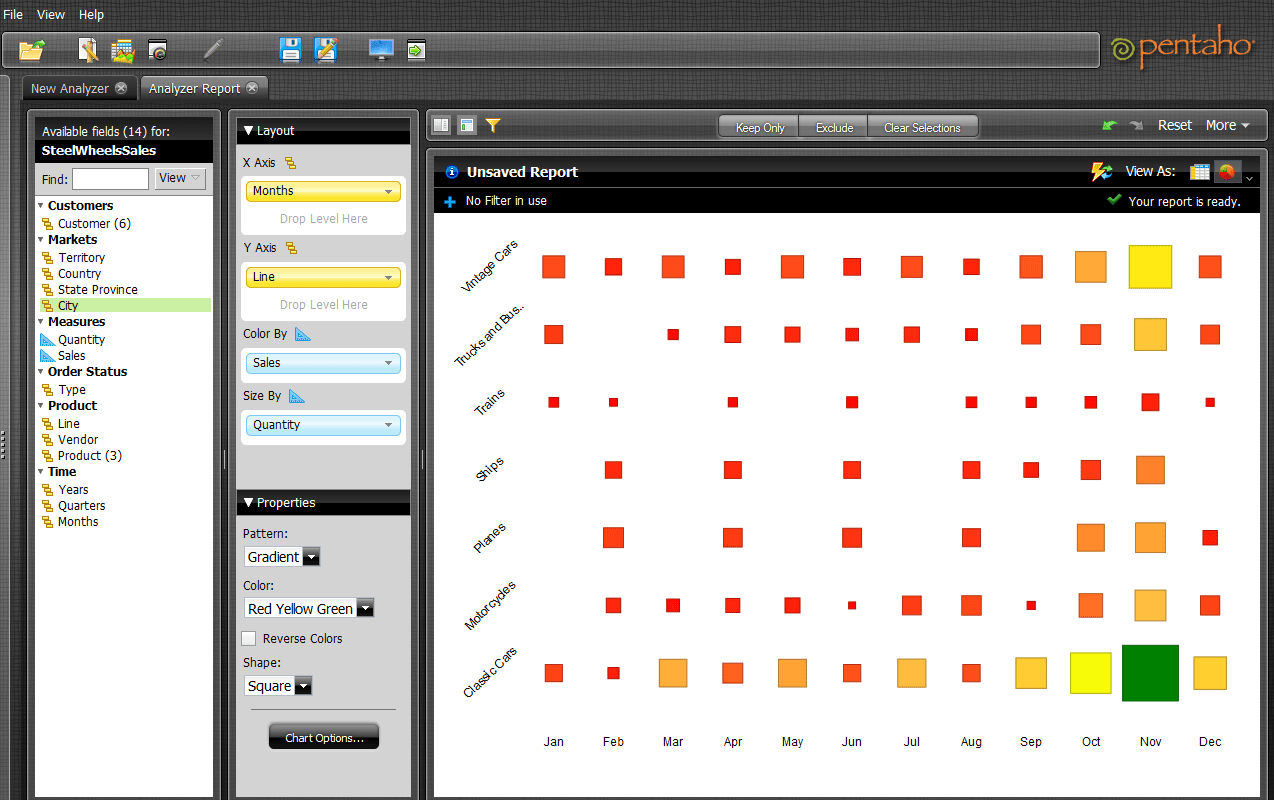

Even though the story is fictional, it’s based on reality. Business users and project managers – such as facility managers, supply chain logistic specialists, even dairy farmers – use Pentaho business intelligence to make their jobs easier and to make smarter, data-driven decisions – just like our fictional friend, Bob.

Who knew BI could be so handy for construction managers?

What is your secret BI story? Drop me a line.

– Farnaz Erfan, Product Marketing, Pentaho